The

Effect of Temperature of Engine Oil on Viscosity

By Jacob Harvey

Period 6

Background / Procedure and Design

/ Materials / Experiment / Procedure / Calculations / Important Measurements / Results

/ Calculating Error / Graphing Data / Evaluation / Conclusion / Links / Bibliography / Return to Research

The invention of the gasoline combustion engine changed the lives

of millions of people around the world, helping humans traverse land much

faster than possible via horse or on foot. However, the refined technology of

modern gasoline engines is taken for granted by many. One of the most important

things an engine requires in order to function (besides fuel and air) is oil,

whether it be mixed with the fuel in a two-stroke application, or utilized

outside the combustion chamber in a four-stroke design. Having participated in

motocross racing and blown up my own fair share of engines, I wanted to better

understand the variables that allow engine oil to lubricate, especially at

different temperatures. Considering the Pacific Northwest experiences

significant changes in temperature year round, understanding the way heat

affects the viscosity of engine oil is keen in preserving the life of a four

cycle gasoline engine. If engine oil is too viscous, it can cause the engine to

lose its efficiency, but if it is too thin, you risk causing permanent damage

to the engine.

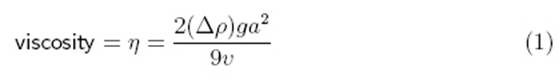

According

to Sciencebuddies.com, viscosity can be calculated using the following

equation/method (answer in g/cm·s):

“The variable commonly used to represent viscosity is the Greek

letter "eta" (η). The variable commonly used to represent

density is the Greek letter "rho" (ρ) ... The other

variables in the equation are g, for the acceleration due to gravity

(981 cm/s2), a for the radius of the sphere (in cm), and v

for the average velocity of the sphere as it falls through the fluid (in cm/s).

The result is in units of poise (g/cm·s).”

Research question: What is the relation

between temperature and viscosity of 10w-30 motor oil, and how does the

potential change in viscosity allow engine oil to lubricate at high and low

operating temperatures?

Hypothesis:

I hypothesize that as

the temperature of the oil approaches normal engine operating temperatures

(90º-100º C), the viscosity will decrease exponentially (become thinner) before

leveling off, because the marble will fall faster as the viscosity decreases.

Variables:

In my experiment, the independent

variable I changed was the temperature in Celsius of the 100ml of 10w-30

oil. The dependent variable was the rate at which the marble fell through

the 100ml of oil inside the graduated cylinder, which I used to calculate

another dependent variable, the viscosity of the fluid at each given

temperature. The variables of my research which remained constant

included the marble’s radius, volume and mass, the volume of the mass of the

oil, the distance traveled by the marble, the change of density (density of

marble - density of oil), and the acceleration of gravity (981 cm/s/s).

Chevron supreme 10w-30 motor oil

100ml Graduated Cylinder

Thermometer (able to read

decimals of degrees)

Marble (1.5875cm diameter)

Spoon (for retrieving the

marble)

Tweezers (for dropping the marble at the surface of the oil)

Stopwatch (phone app)

Video Recording Device (Ipad)

Hot Plate (for heating the

oil)

Ice (for cooling the oil)

Pan (placed the graduated

cylinder inside with water to manipulate temperature)

Scale (measuring weight of

oil and marble in grams)

Newspaper (For cleanup)

For my experiment, after

laying out a few newspapers in my workspace, I poured 100ml of Chevron supreme

10w-30 motor oil into a graduated cylinder. I took a marble and measured the

diameter (1.5875cm) and mass (6g), then measured the depth of the graduated

cylinder from the 100ml mark (11.5cm), and the mass of the 100ml of oil (87g)

to use in my viscosity calculations later. Throughout my experiment, I utilized

the same marble and the same volume and type of oil. Since my experiment relies

on changing the temperature of the oil in the graduated cylinder, I placed the

graduated cylinder in a pot of water, and either heated it on a hotplate to

increase the temperature or added ice to the pot to decrease it. To gather my

data, once I manipulated and measured the temperature of the oil using a

thermometer, I set the graduated cylinder next to my phone with the stopwatch

app running in front of an Ipad, and recorded

slow-motion video as I dropped the marble from just below the surface of the oil

using a pair of tweezers. After the marble reached the bottom of the graduated

cylinder, I stopped the video and retrieved the marble from the oil with a

spoon, added more oil if necessary, and repeated the experiment so I would have

3 points of data for each temperature value. Once I had three videos per each

temperature value, I reviewed the footage and calculated the change in time by

subtracting the time shown on the phone when the marble reached the bottom by

the time displayed when the marble began to fall. Using Google sheets, I made a

table of the temperature and the recorded fall times, and graphed a scatter

plot of oil temperature vs. time taken for the marble to drop, as well as oil

temperature vs. the average time taken to drop. I also calculated uncertainty

of the average time, and used the distance traveled by the marble divided by

the average time to calculate the average velocity in cm/s of the marble.

Finally, by calculating the change in density, radius of the marble, and the

average velocity of the marble, I was able to calculate the viscosity of the

oil (see Calculating Viscosity), and graphed the temperature vs.

each time taken to fall, temperature vs. average time, and temperature vs.

viscosity.

Calculating Viscosity:

Using the formula from the

sciencebuddies.com website, I was able to calculate viscosity using the data I

gathered. However, I first had to calculate the change in density (density of

marble subtracted by density of the oil = 1.9943 g/cm3), and the average

velocity of the marble at each temperature (v=cm/s, 9.9125cm / avg. marble drop

time). I used the following variables to plug into my equation, recorded

viscosity in g/cm*s, and graphed the results.

Calculated Variables

Δρ

(change in density) = 1.9943 g/cm3 g(gravity)=981

cm/s/s a(radius of marble)=0.79375cm

v(velocity of

marble)=cylinder depth (9.9125cm) / Avg. time (s) recorded at a given

temperature

Small

marble diameter = 1.5875cm

Small

marble mass = 6g

Distance

traveled by marble (11.5cm-1.5875cm) = 9.9125cm

100ml of

Chevron supreme 10w-30 motor oil

Mass of

100ml of oil = 87g

|

Times in s |

|||||||

|

Temperature(ºC) |

Trial 1 |

Trial 2 |

Trial 3 |

Avg. Time |

Uncertainty (+/-) |

Avg Velocity (cm/s) |

Viscosity(g/cm*s) |

|

2 |

1.14 |

1.18 |

1.11 |

1.1133 |

0.035 |

8.9037 |

30.7640 |

|

4 |

1.05 |

0.99 |

1.08 |

1.0400 |

0.045 |

9.5313 |

28.7385 |

|

8 |

1.00 |

0.98 |

1.10 |

1.0267 |

0.060 |

9.6547 |

28.3710 |

|

12 |

0.81 |

0.69 |

0.73 |

0.7433 |

0.060 |

13.3358 |

20.5398 |

|

16 |

0.55 |

0.67 |

0.61 |

0.6100 |

0.060 |

16.2500 |

16.8563 |

|

20 |

0.48 |

0.46 |

0.48 |

0.4733 |

0.010 |

20.9434 |

13.0788 |

|

24 |

0.46 |

0.44 |

0.47 |

0.4567 |

0.015 |

21.7046 |

12.6201 |

|

28 |

0.41 |

0.48 |

0.46 |

0.4500 |

0.035 |

22.0278 |

12.4349 |

|

32 |

0.43 |

0.38 |

0.40 |

0.4033 |

0.025 |

24.5785 |

11.1445 |

|

36 |

0.35 |

0.36 |

0.34 |

0.3500 |

0.010 |

28.3214 |

9.6716 |

|

40 |

0.33 |

0.31 |

0.34 |

0.3267 |

0.015 |

30.3413 |

9.0278 |

|

44 |

0.30 |

0.32 |

0.28 |

0.3000 |

0.020 |

33.0417 |

8.2900 |

|

48 |

0.28 |

0.31 |

0.27 |

0.2867 |

0.020 |

34.5745 |

7.9224 |

|

52 |

0.29 |

0.27 |

0.30 |

0.2867 |

0.015 |

34.5745 |

7.9224 |

|

56 |

0.29 |

0.26 |

0.27 |

0.2733 |

0.015 |

36.2697 |

7.5522 |

|

60 |

0.28 |

0.30 |

0.29 |

0.2900 |

0.010 |

34.1810 |

8.0136 |

|

64 |

0.24 |

0.26 |

0.27 |

0.2567 |

0.015 |

38.6151 |

7.0934 |

To calculate the error for each average time, I subtracted the

highest time value by the lowest time value, and then divided the result by 2.

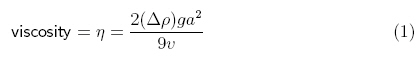

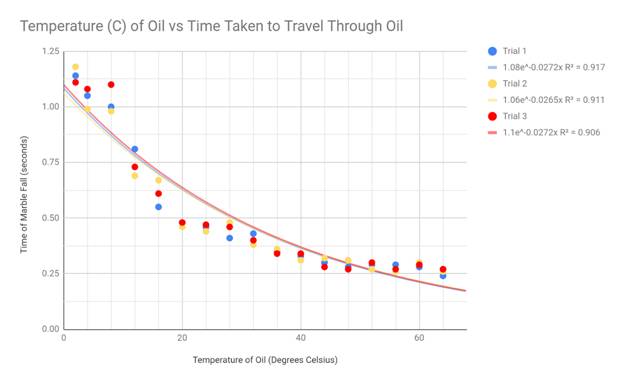

To best display my results, I made scatter plot graphs and drew exponential

lines of best fit. I chose the scatter plot as my graphing format because my

data creates a spread, yet still generally fits a negative exponential curve.

This shape is the reason I used an exponential trend line in each of my graphs.

My hypothesis stated that the viscosity should suggest an exponentially

negative correlation with the temperature of the engine oil, and this

correlates with my data. Although there are some outliers present in the

extremes of my data (cold and hot temps), the exponential decay trend line fits

my graph the best. Because the viscosity equation divides my constant variables

by 9*velocity, and the velocity of the marble increased with temperature, my

data appears in an exponential fashion.

When applying these results

to real-world mechanics, there are some important things to consider. 10w-30

motor oil is engineered to act as single viscosity 10w grade oil at cold

temperatures, but at normal operating temperature it will have the viscosity of

30 grade oil.

Although certain facets of my experiment such as the thermometer reading

degrees to the tenth and the use of video analysis for timing the marble drop

helped control some of the error in my data, there are some key points which

may have caused errors. One of the most prominent facets of my research that

produced error was when dropping the marble using tweezers, the marble would

run the risk of hitting the side of the graduated cylinder before reaching the

bottom, or the tweezers would accidently grip the marble when trying to release

it. This could be addressed by creating a better system for dropping the

marble more instantly and vertically.

Other sources of error

include the nature of my measurement devices, including my thermometer, ruler,

and scale, and these issues could be addressed with more advanced/precise

methods of measurement. Another struggle I encountered was that it became

increasingly difficult to accurately record times when the temperature

approached hotter temperatures, as the marble would take less than a third of a

second to reach the bottom of the graduated cylinder.

Additionally, I struggled to

keep temperature constant while collecting data for extreme temperatures,

specifically with heat. This was likely due to the fact that I conducted my

experiment in a cold basement (approximately 16º C), and if the environment

could be adjusted to match the temperature of the oil, this would have less

effect on my research.

Here’s

a similar experiment: http://csef.usc.edu/History/2003/Projects/J1531.pdf

This

is the engine oil I used, Chevron 10w-30, for sale on Amazon: https://www.amazon.com/Chevron-Supreme-10W-30-Motor-Oil/dp/B00M1Y2S44

Chevron’s

official site: https://www.chevron.com/

This

site has background info for a simplified version of the experiment: https://www.sciencebuddies.org/science-fair-projects/project-ideas/MatlSci_p019/materials-science/viscosity-of-motor-oil.

More background on engine oil viscosities: https://www.motorstate.com/oilviscosity.htm

Elert,

Glenn. “Viscosity – The Physics Hypertextbook.”

Free Fall – The Physics Hypertextbook,

1998, www.physics.info/viscosity/.

Renneboog,

Richard M.J. “Oil Viscosity.” ScienceIQ.com, www.scienceiq.com/Facts/OilViscosity.cfm.

“What Does SAE 10W-30 Stand For?” Tomorrows Technician, 18

Nov. 2017, www.tomorrowstechnician.com/service-advisor-what-does-sae-10w-30-actually-mean/.

Science

Buddies Staff. "The Viscosity of Motor

Oil." Science Buddies, 28 July 2017, https://www.sciencebuddies.org/science-fair-projects/project-ideas/MatlSci_p019/materials-science/viscosity-of-motor-oil. Accessed 24 Feb.

2019.