The Guillotine

A Series of Unfortunate

Beheadings

Jennifer Conner

Table

of Contents:

Introduction

.:. Review of Literature .:. Statement

of the Problem .:. Hypothesis .:. Materials

.:. Method .:. Results .:. Uncertainty

.:. Graph .:. Discussion

.:. Sites to Execute .:. Bibliography

.:. Return to Research Page

Introduction:

The guillotine has had a mysterious, albeit gruesome, history. Dr. Joseph-Ignace

Guillotine did not invent the guillotine, but his name has been associated with

the machine because “he was the one to propose that a mechanical device carry

out the death penalty” (Fabricius). In addition, Dr. Antoine Louis, Secretary of

the French College of Surgeons, is credited as the actual designer of the

guillotine (Benet 413).

The guillotine has had a mysterious, albeit gruesome, history. Dr. Joseph-Ignace

Guillotine did not invent the guillotine, but his name has been associated with

the machine because “he was the one to propose that a mechanical device carry

out the death penalty” (Fabricius). In addition, Dr. Antoine Louis, Secretary of

the French College of Surgeons, is credited as the actual designer of the

guillotine (Benet 413).

The guillotine does not have a concrete place in today’s modern world as a mode

of execution. The last recorded execution using a guillotine was in France,

during 1977, after which, capital punishment was outlawed (in all forms).

However, the first guillotine machines date back to the 13 00’s A.D., nearly 400

years before the French Revolution would make guillotines famous. One of the

first recorded executions with a guillotine-like machine was in 1307 A.D. in

Ireland. The drawing on which the account is based, called, “The Execution of Murcod Ballagh,”

(right) clearly shows a straight blade in contrast to the oblique ones

of the later time periods (Fabricius). The Halifax Gibbet and The Maiden, famous

guillotine-like machines in the 15th and 16th centuries, were fashioned with

rounded blades. It wasn’t until 1792 (left) that an oblique blade was tried and made

effective as a means of execution. Further advancements to the machine include a

new release mechanism (Leon Berger) and a shield to hide the blade (Nicolas Roch).

00’s A.D., nearly 400

years before the French Revolution would make guillotines famous. One of the

first recorded executions with a guillotine-like machine was in 1307 A.D. in

Ireland. The drawing on which the account is based, called, “The Execution of Murcod Ballagh,”

(right) clearly shows a straight blade in contrast to the oblique ones

of the later time periods (Fabricius). The Halifax Gibbet and The Maiden, famous

guillotine-like machines in the 15th and 16th centuries, were fashioned with

rounded blades. It wasn’t until 1792 (left) that an oblique blade was tried and made

effective as a means of execution. Further advancements to the machine include a

new release mechanism (Leon Berger) and a shield to hide the blade (Nicolas Roch).

The improvements to the guillotine highlight important facts relating to testing

of the blade. Namely, the blade transitioned from a solid slab, which was more

effective in breaking a person’s neck, to a slanted blade, which behaved like a

sword.

Due to the fact that there is little recorded history of the machines between

the fourteenth and eighteenth centuries, questions arise as to why the angle of

the blade was changed. But most of these questions focus around a single query:

Is an oblique blade more efficient than its parallel counterpart?

TOC

Review of Literature:

There have been no comprehensively recorded studies of the guillotine itself, as

any improvements were made before the 19th century. The evolution of the blade,

one of the few variables involved with the guillotine, was altered to make the

device more efficient. This goal was met and the design has remained nearly

unchanged through the 19th, 20th, and 21st centuries.

TOC

Statement of the Problem:

The purpose of this experiment was to determine if an oblique blade was more

efficient than one that was straight. The Dependent variable is the angles of

the blades while the Independent Variable is the different heights the blade was

raised.

TOC

Hypothesis:

The blades with an angle, specifically between forty-five and seventy-five

degrees, will be the most efficient (slice through the most clay at the lowest

height) because the force of the blade will hit a smaller area, thus slicing the

clay better.

TOC

Materials:

• Milk Crate

• Hollow Metal Rod approx 1.3m (cut into 2 (.54m) sections and 2 (.10m)

sections)

• .1016m (width) piece of metal .1524m long

• Wood Block 6cm x 2.81cm with a 2.mm wide (2 cm deep) cut across the top

• 6 razor blades

• Ruler

• Modeling Clay

• Protractor

TOC

Method:

The first step was to establish the basics; determine how to measure

“efficiency”, what type of setup to use, find what angles of the blades to test,

and create a procedure.

Although initial/practice testing demonstrated that the oblique blades seemed to

be better than the straight one, there needed to be an empirical way to show

such results. Because modeling clay was one of the original substances that was

used for testing the blade, it seemed plausible that it could be used as a part

of the experiment. During mini-trials, it was noticed that when the blades did

not slice all the way through the clay, a smooth indentation was left. Thus, the

progress of the blade could be measured by how far it sank into the clay. In

order to relate that measurement to the efficiency of the blades, the blade

could be dropped from different heights. If the oblique blades were more

efficient than the straight one, then they would slice through the clay deeper,

at lesser heights.

Although initial/practice testing demonstrated that the oblique blades seemed to

be better than the straight one, there needed to be an empirical way to show

such results. Because modeling clay was one of the original substances that was

used for testing the blade, it seemed plausible that it could be used as a part

of the experiment. During mini-trials, it was noticed that when the blades did

not slice all the way through the clay, a smooth indentation was left. Thus, the

progress of the blade could be measured by how far it sank into the clay. In

order to relate that measurement to the efficiency of the blades, the blade

could be dropped from different heights. If the oblique blades were more

efficient than the straight one, then they would slice through the clay deeper,

at lesser heights.

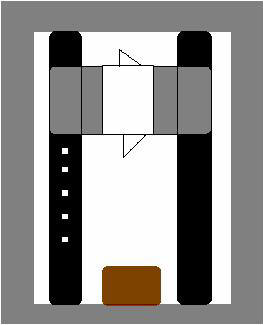

The setup needed to be designed with precision in order to minimize friction

while maximizing usage. The initial guillotine design was built inside a .3048meter x .5334m crate that would stabilize the structure. Next, two metal

rods were measured (.54864m); these would serve as the “tracks” to which the

blade apparatus was attached. The casings (10.16cm) that went over the two metal

rods fit well; there was less than a millimeter clearance between the two. This

helped minimize “rattling”, or excess movement, by the blade, while not creating

a substantial amount of friction. The casings that slid up and down the metal

“tracks” were also sanded on the edges and about one inch into the tube. This

was done because the casings were cut from a hollow metal bar; by sanding it

reduced or eliminated the metal shavings that remained. The casings were

attached on the front and back with two pieces of lightweight wood via hot glue.

Next the blade apparatus was put on the “tracks”, and the metal rods were

secured in place. A “chopping block” was held to the bottom of the guillotine;

it had a 2.5 millimeter cut across in order to catch the blade. It was 6

centimeters long and 3.81cm tall. The blade would be attached by metal clips

that would hold it to the sliding apparatus. Measurements were also drawn along

the side in order to test the hypothesis. After multiple tests, this setup

seemed to work okay. However, problems were encountered; the metal clips did not

always hold the blade on, none of the sharp blades (straight or oblique) were

cutting through the clay, and it was difficult to place the blade in the same

position every time. Thus, the decision was made to go to a metal design. The

same steps were used, from the metal rods to the blade device. The difference

was that the there was a piece of thin sheet metal (attached to the casings by

zip ties) that the blades would attach to via two screws. This gave the blade

more force (increased mass) and assured that the blade was held securely in

place in the same position. This design also allowed for two blades to be

attached on plate. This was especially important as there were only limited

materials available.

.3048meter x .5334m crate that would stabilize the structure. Next, two metal

rods were measured (.54864m); these would serve as the “tracks” to which the

blade apparatus was attached. The casings (10.16cm) that went over the two metal

rods fit well; there was less than a millimeter clearance between the two. This

helped minimize “rattling”, or excess movement, by the blade, while not creating

a substantial amount of friction. The casings that slid up and down the metal

“tracks” were also sanded on the edges and about one inch into the tube. This

was done because the casings were cut from a hollow metal bar; by sanding it

reduced or eliminated the metal shavings that remained. The casings were

attached on the front and back with two pieces of lightweight wood via hot glue.

Next the blade apparatus was put on the “tracks”, and the metal rods were

secured in place. A “chopping block” was held to the bottom of the guillotine;

it had a 2.5 millimeter cut across in order to catch the blade. It was 6

centimeters long and 3.81cm tall. The blade would be attached by metal clips

that would hold it to the sliding apparatus. Measurements were also drawn along

the side in order to test the hypothesis. After multiple tests, this setup

seemed to work okay. However, problems were encountered; the metal clips did not

always hold the blade on, none of the sharp blades (straight or oblique) were

cutting through the clay, and it was difficult to place the blade in the same

position every time. Thus, the decision was made to go to a metal design. The

same steps were used, from the metal rods to the blade device. The difference

was that the there was a piece of thin sheet metal (attached to the casings by

zip ties) that the blades would attach to via two screws. This gave the blade

more force (increased mass) and assured that the blade was held securely in

place in the same position. This design also allowed for two blades to be

attached on plate. This was especially important as there were only limited

materials available.

The final step was to determine which angles to use. Zero degrees was clearly

needed; however, the other oblique angles would be harder to choose. Due to

limited materials, only six angles, in total, could be used. After looking at

various angles on a protractor, five representative angles were chosen: 0

degrees, 30 degrees, 45 degrees, 75 degrees, and 90 degrees. With one angle

option left, a miniature test was done to see where another angle would fit in.

Because the 45 and 75 degree angles cut the farthest into the clay, a 60 degree

angle was chosen in hopes of being better than both. The blade angles were

drawn, with a protractor, onto the plate that attached to the blade apparatus.

The blades were then hot-glued into place, with all blades extending 1.5 cm from

the sliding part.

Thus, all of the materials were ready. The procedure was simple; the guillotine

would be raised to a mark (from 4.445cm to 29.84cm) and released where it would

hit a 1.5x1.5x1.5cm clay cube. The same piece of clay was used for all trials,

and was reworked into a cube for each trial. This kept the clay limber and at a

similar temperature for each test. After each drop, the blade was quickly lifted

to help avoid the sheer mass of the sliding apparatus from pushing the blade

deeper. Next, a ruler would measure how far into the clay the blade had fallen.

Eleven different heights were used for the six angles.

TOC

Results:

Raw Data

(The height measurements are exact because it was originally measured in inches.

The numbers were simply converted)

TOC

Uncertainty:

There are three possible uncertainties in this experiment. The first is the

angles of the blades. The angles were found using an equipment protractor (it

was a medium scaled one) and drawing onto the metal sheets. The uncertainty

would most likely be plus or minus two degrees, as the increments were ten

degrees apart. The next uncertainty it for the height at which the blade was

dropped. In order to measure the distances, a tape measure was used. However, it

was marked while it was in position, probably making some of the measurements

plus or minus two centimeters. The last uncertainty is the most important. It is

the amount of clay sliced through. The main problem here is that because the

blades only came down 1.5cm, there was opportunity for the metal plate holding

it to hit the clay. This would smash the top part of the clay. This is

important, as when the indentation was measured, the smashed part may be

overlooked and a smaller amount of material would be recorded as sliced.

TOC

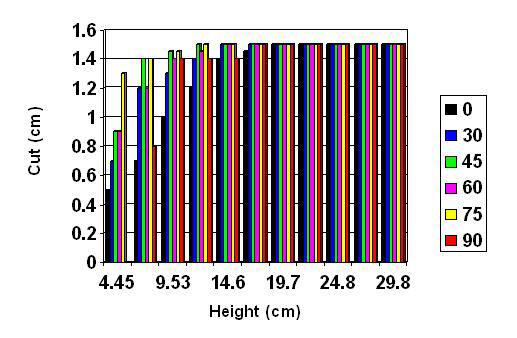

Graph of Data:

TOC

Discussion:

As evident in the data table, my hypothesis is well supported. In my hypothesis,

I stated that not only the blades with an angle would fare better than the zero

degree angle, but that the angles between 45 and 75 would be the most efficient.

In the data table, the angled blades were able to slice through the clay at

least seven centimeters before the zero degree angle. The 45 and 75 degree

angles were the first to cut through the clay after a 12.065cm drop. My initial

reaction to this was that the 60 degree angle would therefore be the best

because 60 is the average of the two. However, this was not the case; the 60

degree angle cut through the clay 2 cm after the 45 and 75 degree angles. The 30

degree angle did as well as I expected it to, while the 90 degree one took me by

surprise. It seemed unusual that it would cut through the same amount of

material at three different heights, but I retested it, and received the same

results. The zero degree angle also performed how I thought it would. It tended

to smash the area around the cut more than any other angle. The uncertainty here

is probably the greatest among any of the other blades because, as

aforementioned, the metal sheet that the blade attached to could also hit the

clay. Therefore, those numbers would be lower. It is also interesting to note

that after a certain height, (19cm), all the blades were able to slice through

the clay.

To make sure the results contained fewer errors, I tested the angles randomly.

This was done because I was working with clay, and it tended to be slightly hard

at first. Nevertheless, the more I worked with it, the more it stabilized. I

also tried to avoid errors in measuring, so I used a range of rulers (some

small, some big) in order to get the closest to the correct measurement.

Nonetheless, I could have erred in other ways, such as: the lack straightness of

the angle on the blade apparatus, dullness occurring in the blades, the chopping

block cut that caught the blade could have been too wide (causing more smashing

than slicing), and there could have been excess friction between the “tracks”

and the casings.

To put these findings in a historical setting, I think that the blades did

change due to a need for more efficiency. With oblique blades cutting through

more at a lesser height, it would be more economical for executioners to use

this style.

To further research in this field, I would look at the force that the blades

exert onto on object. This could potentially improve the efficiency of the less

oblique blades due to more mass. Also, the length and width of the blade exposed

could be another type of experiment done; this may improve the amount sliced as

the blade could make a clean cut without any smashing. Most pictures of

guillotines show that the blade is merely held with a rope, where it is both

long and wide. It may also be interesting to test the guillotine with higher

height numbers, although after a while, one may run into friction errors and

uncertainties.

TOC

Sites to Execute

http://www.metaphor.dk/guillotine/Pages/Guillot.html

- This site is probably the most reliable and

the most thorough of any of the sites I found and it has information on all

areas of the guillotine.

http://europeanhistory.about.com/cs/frenchrevolution/a/Guillotine.htm

- This site has a very lengthy history of the

guillotine and serves those most interested in the development of weapons in

general.

TOC

Bibliography:

Author Unknown; Benet’s Reader’s Encyclopedia; Edition 3, 1987; New York; p. 413

Author Unknown; U.S. News & World Report; July 17, 1989; Volume 107, N. 3;

pp.46-9

Author Unknown; Guillotine; October 25th, 2005; http://en.wikipedia.org/wiki/Guillotine

Fabricius, Jorn; The Guillotine Headquarters; October 24th, 2005; http://www.metaphor.dk/guillotine/Pages/Guillot.html

Wilde, Robert; The Guillotine; October 25th, 2005; http://europeanhistory.about.com/cs/frenchrevolution/a/Guillotine.htm

TOC

Return to Research Page

The guillotine has had a mysterious, albeit gruesome, history. Dr. Joseph-Ignace

Guillotine did not invent the guillotine, but his name has been associated with

the machine because “he was the one to propose that a mechanical device carry

out the death penalty” (Fabricius). In addition, Dr. Antoine Louis, Secretary of

the French College of Surgeons, is credited as the actual designer of the

guillotine (Benet 413).

The guillotine has had a mysterious, albeit gruesome, history. Dr. Joseph-Ignace

Guillotine did not invent the guillotine, but his name has been associated with

the machine because “he was the one to propose that a mechanical device carry

out the death penalty” (Fabricius). In addition, Dr. Antoine Louis, Secretary of

the French College of Surgeons, is credited as the actual designer of the

guillotine (Benet 413). 00’s A.D., nearly 400

years before the French Revolution would make guillotines famous. One of the

first recorded executions with a guillotine-like machine was in 1307 A.D. in

Ireland. The drawing on which the account is based, called, “The Execution of Murcod Ballagh,”

(right) clearly shows a straight blade in contrast to the oblique ones

of the later time periods (Fabricius). The Halifax Gibbet and The Maiden, famous

guillotine-like machines in the 15th and 16th centuries, were fashioned with

rounded blades. It wasn’t until 1792 (left) that an oblique blade was tried and made

effective as a means of execution. Further advancements to the machine include a

new release mechanism (Leon Berger) and a shield to hide the blade (Nicolas Roch).

00’s A.D., nearly 400

years before the French Revolution would make guillotines famous. One of the

first recorded executions with a guillotine-like machine was in 1307 A.D. in

Ireland. The drawing on which the account is based, called, “The Execution of Murcod Ballagh,”

(right) clearly shows a straight blade in contrast to the oblique ones

of the later time periods (Fabricius). The Halifax Gibbet and The Maiden, famous

guillotine-like machines in the 15th and 16th centuries, were fashioned with

rounded blades. It wasn’t until 1792 (left) that an oblique blade was tried and made

effective as a means of execution. Further advancements to the machine include a

new release mechanism (Leon Berger) and a shield to hide the blade (Nicolas Roch).