Introduction

Background .:. Statement of Problem.:. Review of Literature.:. Hypothesis.:. Procedure.:. Data & Graphs.:. Evaluation.:. Works Cited .:. Go Up

For our research project we were aiming to determine the tensile strength of nichrome wire at various currents. The alloy nichrome is composed of nickel and chromium. The wire we used was composed of 80% Nickel and 20% Chromium. The addition of chromium makes the wire stainless (Smith). Some common applications for the use of nichrome wire are in heating elements and electric ovens. Now it is necessary to first examine what happens within a metal when a current is applied. Running a current through the metal will not only heat the metal, but also increase its resistivity. When the nichrome wire has reached its melting point of 2250 degrees Fahrenheit it’s resistivity will have increased by about 6.5%(www.wiretron.com). In order for the metal to reach it’s melting point there must be enough supplied current to break down the metallic bonds. Therefore a metal which requires a great amount of heat to be melted will have stronger metallic bonds and thus be a stronger metal.

The purpose of this investigation was to determine the tensile strength of nichrome wire while running various currents through it. The strength of the wire is defined as the amount of force in Newtons required to stress and eventually break the wire into two pieces. We also studied our data to see if there was any unique relationship between the wire’s strength and the amount of current supplied.

There are some general and basic things we must first recognize in order to understand our experiment. Wire is formed by pulling a metal rod through smaller and smaller dies until a long thin wire is produced (Whyman). This means that the domains of the metal are stretched and pointed longitudinally through the wire. It is also a known fact that heat and electricity can travel along all metals (www.morelectric.com). Furthermore, Galvery and Marlow define tensile strength as the ability of a test specimen to resist being pulled apart and that the ultimate tensile strength is the maximum stress value obtained on a stress-strain curve.

There are some general properties of metals which need to be considered. One has to do with the makeup of metals on the crystalline level. The electrons of a metal are delocalized, meaning they have the ability to move around, which makes metals generally good conductors. Because of the high mobility that electrons enjoy, the number of electrons available for bonding greatly determines both the conductivity and the melting point of a given metal (media.nasaexplores.com). The melting point determines how much current needs to be applied in order to melt the metal, and is also a key indicator of the strength of the metal. The high electrical resistance of nichrome, combined with its high melting point, make it a very efficient material for converting electrical energy into heat energy (Stwertka).

When we pull on the wire we are stressing it to the point at which it breaks. At the factory stress relieving is used to remove internal stress caused by the forming process. It is done by heating the object to a specific temperature and then during the solidification process the grain size can be controlled and changed (Wright). This is basically what we did except that we did not allow the piece to solidify leaving the grains rather liquid allowing the wire to fracture. This was more evident when supplying the larger currents.

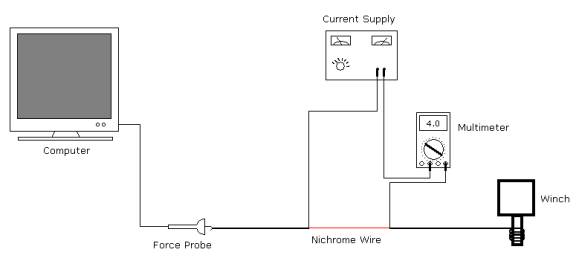

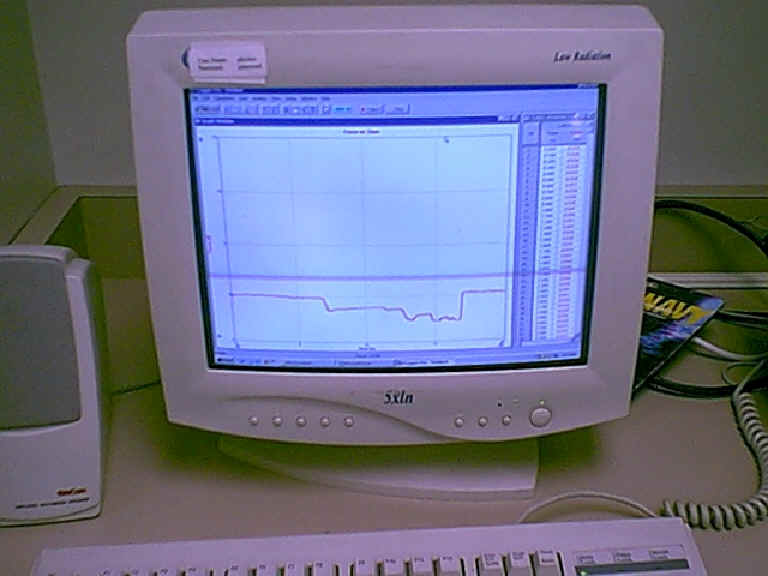

We hypothesized that as the current is increased, it will decrease the tensile strength of the nichrome wire. We expected the correlation between the current and force to be linear. Our constant variable, the length of the wire, was set at ten centimeters. The independent variable being the amount of supplied current was monitored via a multimeter to maintain as much accuracy as possible. The force required to fracture the wire was measured via a force probe that displays its reading on the computer screen as a graph of time vs. force. From the graph we then picked the greatest force reading. Current is defined as a flow of electric charge (I = V/R). Tensile strength is the ability of the wire to resist being pulled apart.

Materials: §

Current supply §

Multimeter Electric winch Two lengths of plastic coated wire §Alligator

clamps §Force

probe §Nichrome

wire

- Securely fasten the plastic-coated wire to both the winch and the force probe.

- Measure 15 cm of nichrome wire and fasten it between the two plastic-coated wires.

- Attach the alligator clamps to the nichrome wire, making sure that they are 10 cm apart.

- Using the electric winch, wind up the plastic-coated wire until the nichrome wire is pulled taught.

- Start the data collection on the computer.

- Turn the current to 2 A and continue recording data until the wire breaks.

- Do two more trials at this current.

- Repeat steps 2 – 7 increasing the current by .5 A every time until 5 A is reached.

|

Current (A) |

Trial 1 |

Trial 2 |

Trial 3 |

|

2 |

2.409 |

2.409 |

2.409 |

|

2.5 |

2.409 |

2.409 |

2.409 |

|

3 |

2.47 |

2.409 |

2.409 |

|

3.5 |

1.564 |

1.554 |

1.524 |

|

4 |

1.124 |

1.064 |

1.199 |

|

4.5 |

0.329 |

0.429 |

0.314 |

|

5 |

0 |

0 |

0 |

|

Current (A) |

Avg. Force (N) |

|

2 |

2.409 |

|

2.5 |

2.409 |

|

3 |

2.429333333 |

|

3.5 |

1.547333333 |

|

4 |

1.129 |

|

4.5 |

0.357333333 |

|

5 |

0 |

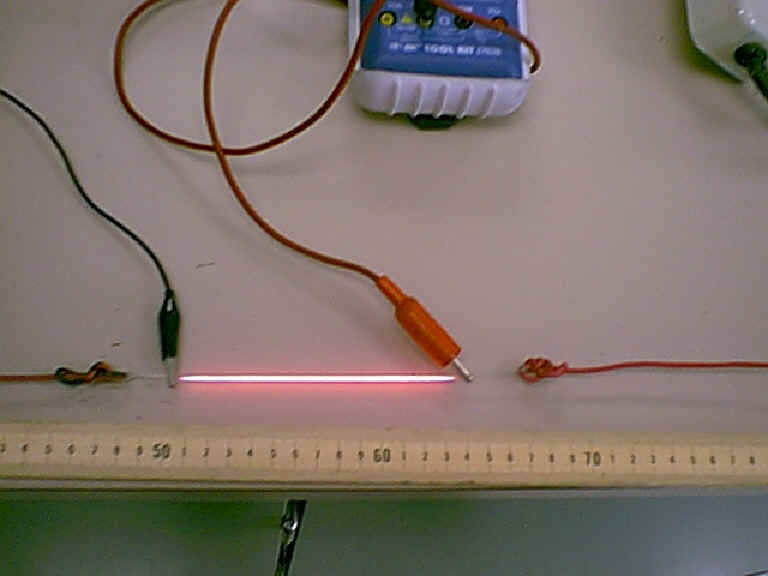

Based on the data we obtained our hypothesis turned out to be wrong. The amount of supplied current and the force required to separate the wire did not turn out to be linear. Instead at 2.0 amperes to about 3.0 amperes the force required to break the wire remained constant at 2.409 N. From 3.0 to 5.0 amperes there is a linear relationship of current vs. force. Coincidently, when we ran 3.5 amperes was first time we began to see the wire really heat up, for example turning orange. So from 3.0 amperes on the force required to break the wire began to drop significantly until there was virtually no force needed to break the wire at 5.0 amperes. From our data we can conclude that when the wire begins to glow the force required to break it decreases as the current is increased. One of our setups weaknesses was the way we pulled on the wire. The electric winch we used at times acted a little jerky. It may have actually been better if we pulled on the wire by hand using a crank of some sort with a long enough arm to create enough torque. By doing it by hand we think we could have actually achieved a smoother break giving us a more accurate force reading. Another weakness and possible inaccuracy to our setup was that as the wire was stretched the current flowing through it would drop somewhat. After noticing this after many practice trials we decided to just make sure we set the current to where we wanted it at the beginning of each pull. We didn’t want to try to keep the current constant as the wire was stretched because we thought it would give us inconsistent and inaccurate results. One little detail that would have been nice to know was the gauge of the wire we were testing. I can only really guess that it was around the .030-.025 inch diameter. An additional improvement to this investigation that we could have done was to have taken more data points and at smaller increments to produce an even better looking graph of our data.

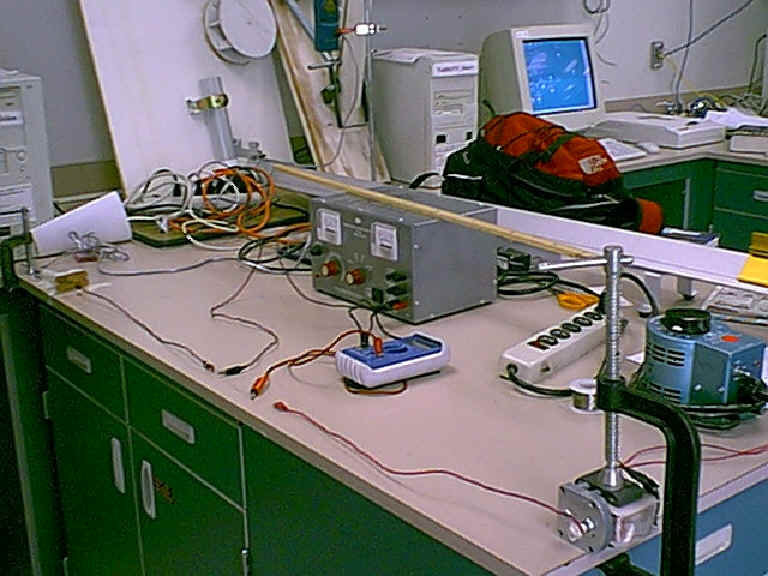

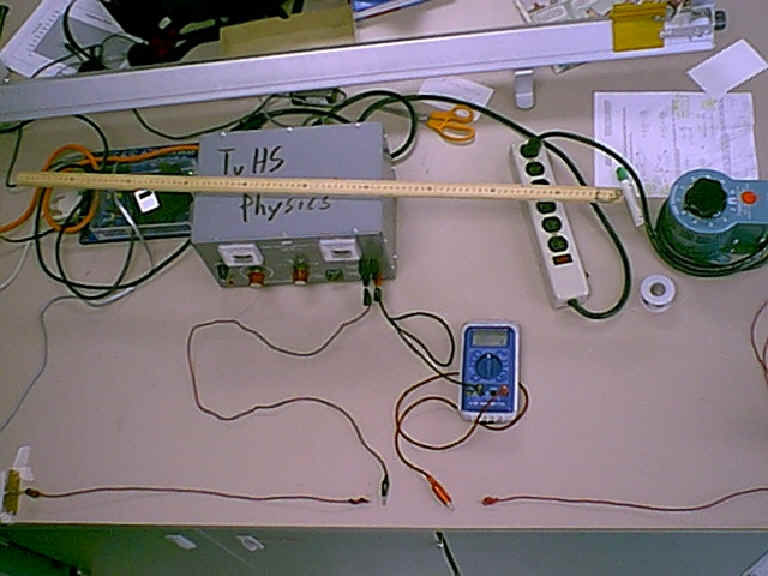

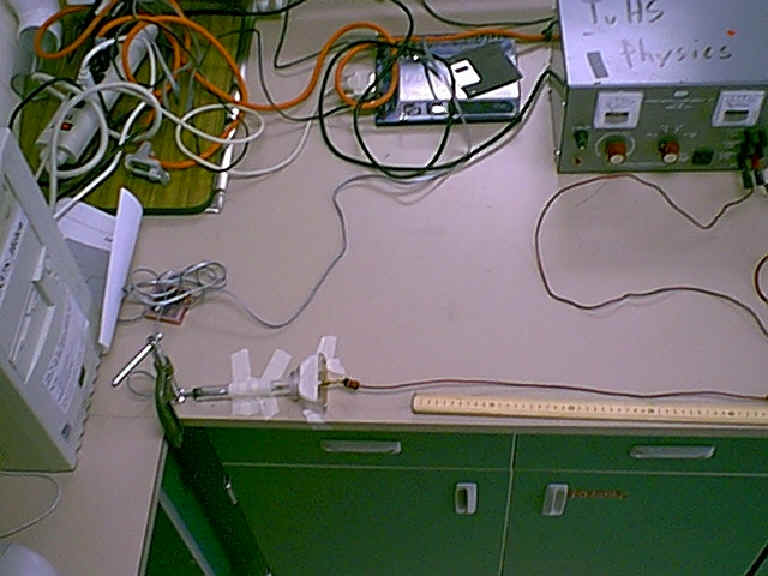

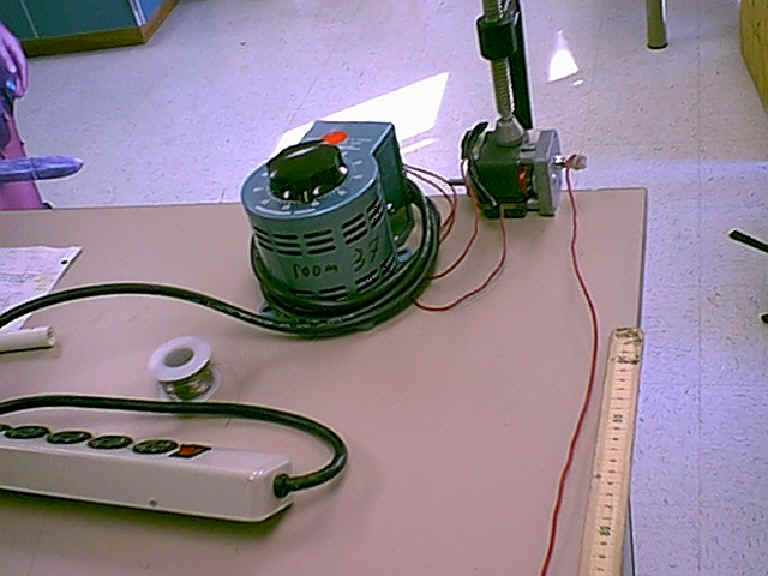

Pictures

Galvery, William and Marlow, Frank. Welding Essentials. New York: Industrial Press Inc., 2001.

Smith, H. Robert. Working with Metal. New Jersey: Time-Life Books, 1981.

Stwertka, Albert. Guide to the Elements. New York: Oxford University Press Inc., 1998.

Whyman, Kathryn. Metals and Alloys. New York: Gloucester Press, 1988.

Wright, R. Thomas. Processes of Manufacturing. U.S.A: The Goodheart-Willcox Company Inc., 1990.

“Nichrome 60 (NiCr60) Resistance Heating Wire.” Electric Heating Assoc., Inc. Oct. 22 2003. <http://www.morelectric.com/nichrome.htm>

“Properties of Alloy.” National Aeronautics and Space Administration. Oct. 22 2003 <http://media.nasaexplores.com/lessons/01-032/9-12_1.pdf>

“Nichrome & Other Resistance Alloys - Technical Data & Properties.” WireTronic Inc. Dec. 28 2003. <http://www.wiretron.com/nicrdat.html>

Web Sites

This website

gives information about temperature characteristics and resistivity of

nichrome wire.

http://www.morelectric.com/nichrome.htm

Another source for temperature and

resistance information.

http://www.wiretron.com/nicrdat.html

This website is

no longer available.

http://media.nasaexplores.com

Information on

electromagnet strength and current flowing through a wire.

http://www.coursework.info/i/49357.html