Evan and

Tegan's Totally Awesome Physics Research page!

Evan and

Tegan's Totally Awesome Physics Research page!

This page is presented in glorious black background and white text to make it less abrasive to your eyes as you read. We are very concerned about your personal comfort as you read our page, and we feel that you will enjoy what we have to say even more if you are at ease while you are here.

Table of Contents

| Introduction | Materials/Procedure | Planning | Results | Conclusion | Bibliography | Related Links | Return to Research Page |

According to thermodynamics, when an

object is heated it causes the velocity of the molecules to increase. As the

velocity of the molecules increases the rate at which the molecules hit the

walls of the object also increases. This results in an increase in the force of

impact on the walls and causes the walls to be pushed out and therefore causes

an increase in the volume of the object itself. Likewise, when metal is cooled

down, the molecular velocity decreases and the force of impact on the walls is

lessened, allowing for a compaction of volume. The research question now

becomes, what effect does the increase in volume of the spring’s coils have on

the spring constant itself? When assessing this question, two potential frames

of reasoning come to mind. One may assume that because the spring volume is

increasing and typically thicker springs typically hold more weight, or have a

higher spring constant, the expansion in volume would allot for an increase in

the spring constant. However, the opposing idea would be that because the

matter of the spring is not increased, simply the volume, the spring would

actually become weaker because the molecules are no longer as tightly packed. However,

the focus of our research is simply to see whether an effect is present, not

why it is or is not. Based upon research, it is our hypothesis that by

increasing the temperature of a steel spring, the increase of volume of the

spring will lead to a decrease in the spring constant. Support for this idea is

as follows,

“Most objects expand when they are heated

and contract when they are cooled. Most objects also get hotter when they are

compressed and cooler when they are expanded. This effect can get complicated

because the values of the elastic module also depend on temperature, usually

getting smaller for higher temperatures” (2000 Oxford Dictionary of Physics).

This

means that as the

temperature increases, the spring constant decreases and a visible weakening of

the spring should be noted.

As far as

accounting for potential room for error there are three main areas that must be

taken into consideration. The first of these is the ability of the spring to

resist deformation. The atomic volume of steel is said to increase

exponentially with its temperature. While

the increase is relatively small, particularly when considering an increase of

almost 2000 Kelvins is required to increase the atomic volume by 1e-3 mm3,

it is still enough to cause a significant change in the ability of the spring

to resist deformation. However, to avoid

this, temperatures will be kept well under 2000 Kelvins.

The second

of these is the possibility of the spring becoming plastically deformed.

Hooke’s Law states that stress is linearly proportional to strain. If the stress is doubled then the strain is

doubled; if the stress is tripled than the strain increases threefold. However, there are limitations to the

validity of Hooke’s Law; it is usually only valid “for strains of far less than

1 percent. In most pure metals, for

example, the elastic limit is reached for strains as small as .001

percent. For larger strains, the object

never reverts exactly to its original shape on removal of the stress but

remains changed to some extent; it is said to be plastically deformed” (1996

Macmillian Encyclopedia of Physics).

The third

potential room for error is creep. “Creep is the term used to describe the

time-dependent plastic flow under conditions of constant load or stress. Whilst creep can occur over the whole

temperature range…with engineering metals and alloys, creep is of practical

importance only at high temperatures” (1972 Creep of Metals at High

Temperatures). However, high

temperatures typically pertain to those close to the melting point of the given

metal, and in this case the temperature to which the steel spring will be

heated will not be within range of its melting point.

Materials: one steel spring, ammeter, power supply, leads A and B,

stand, clamp, paperclip, mass holder (50 grams), and masses (grams).

Procedure:

1)

Locate a stand to suspend the spring

from. The stand should be about ten times longer than the spring (at least).

2)

Attach a clamp to the stand to

suspend the spring from. Make sure that the clamp is at least 5 inches away

from the stand itself so that no contact between the spring and the stand is

made.

3)

Locate a spring to be used. The

spring should have a loop at the top of it perpendicular to the rest of the

coils to allow it to be hung.

4)

Attach the spring so that it is

dangling from the clamp. The spring should form a 90-degree angle with the

clamp and be parallel to the stand. The spring should be hanging straight with

no curve in it.

5)

Hook the ammeter up the power supply.

6)

Attach lead A to the top spring loop;

secure lead B to the bottom spring coil.

7)

Take a paper clip and bend it into a

crescent shape and suspend it from the bottom spring coil.

8)

Attach the mass holder to the paper

clip (the mass holder should be equal to 50 grams).

9)

Run the experiment with approximately

each of the following amounts of current: 0A, 1A, and 3A. For each current use

masses of 50, 100, 150, and 200 grams to stretch the string. Remember that the

mass holder itself has a mass of 50 grams and use only it for the 50 grams

mass. Then add a 50 grams mass to the mass holder for a total of 100 grams and

so on. Record results.

The procedure above was the one used in actually when running

our lab, however, it was not the original one planned. While actually running

our lab we had to account for certain aspects, which in turn required an

alteration to our original procedure. The first of these would be that it was

anticipated we would be able to use actual temperature calculations to mark the

decrease in the spring constant. However, it became increasing difficult to

find a way to heat the spring in the first place. We originally had planned to

heat the spring in water and use a thermometer to get the temperature of the

water and then assume that temperature would equal the temperature of the

spring because we would allow it to remain submerged for some time. However, we

decided this would leave too much room for error because the container the

water was heated in would have to be exposed to some source of heat, obviously,

and we knew that the spring would sink to the bottom of the container and come

in direct contact with the container. This would potentially cause the spring

to be laid up against the part of the container being heated and the heat

source would cause the container to be hotter in that spot then that actual

over all temperature of the water. However, because we would be relying on the

temperature reading of the water and not the temperature of the actual

container directly above the heat source, we would have an inaccurate

temperature reading. Also, it would take a lot of time to heat each spring and

water to different temperatures and we could not be certain as to how long the

spring would need to be submerged before taking on the temperature of the water

in the first place. Instead we decided to run current through the spring, which

would cause an increase in the spring temperature, and use qualitative data. We

found that the increase in current caused a notable change in temperature

simply by touching the spring and therefore could tell the current was having the

desired effect on our spring. We also made sure that we attached connector

cables A and B directly to the endpoints of the spring. This was done out of

fear that attaching the connector cables anywhere other than directly to the

spring would cause a discrepancy between the actual amount of current running

through the spring and the reading of the ammeter because it would not be

running only through the spring but through other apparatus.

1

1

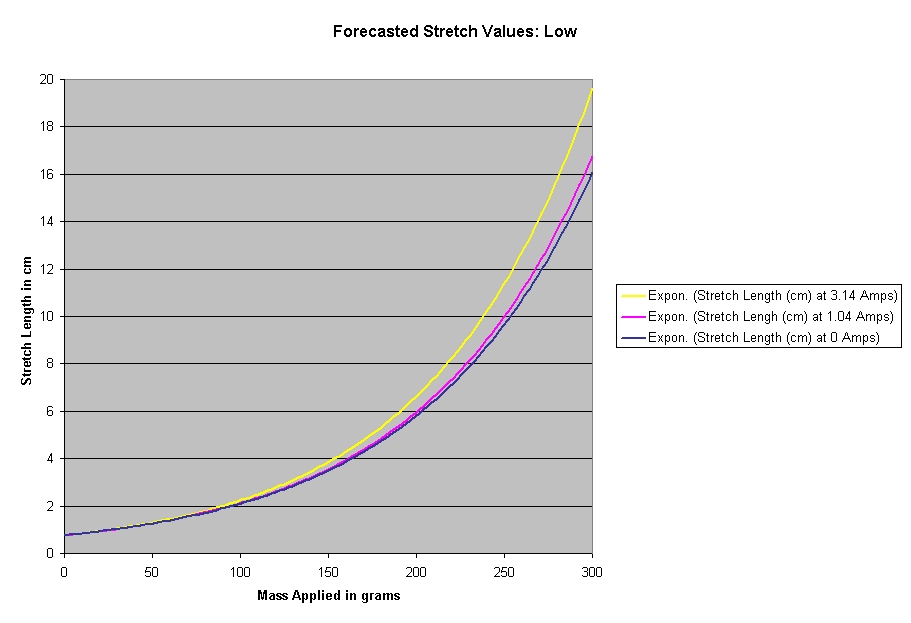

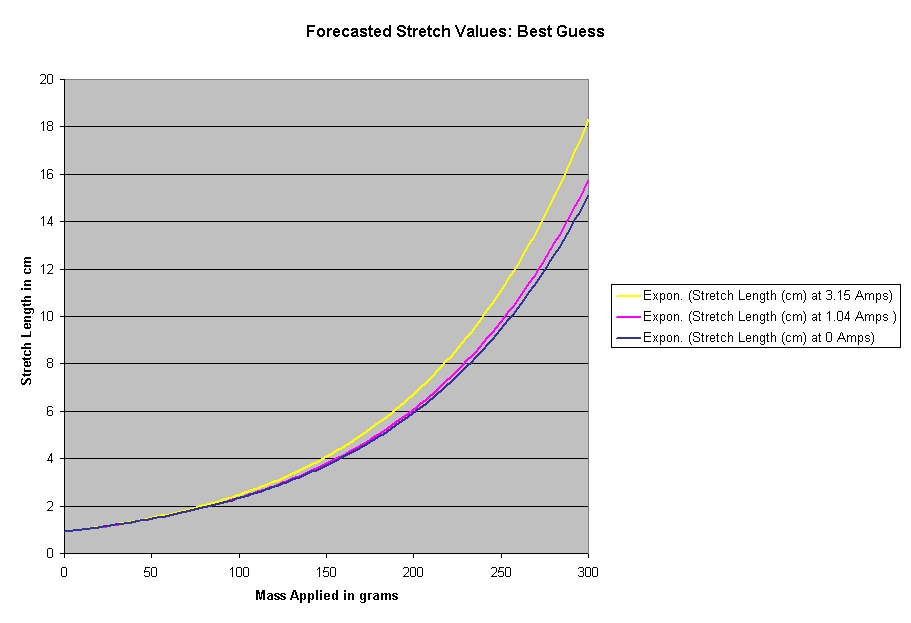

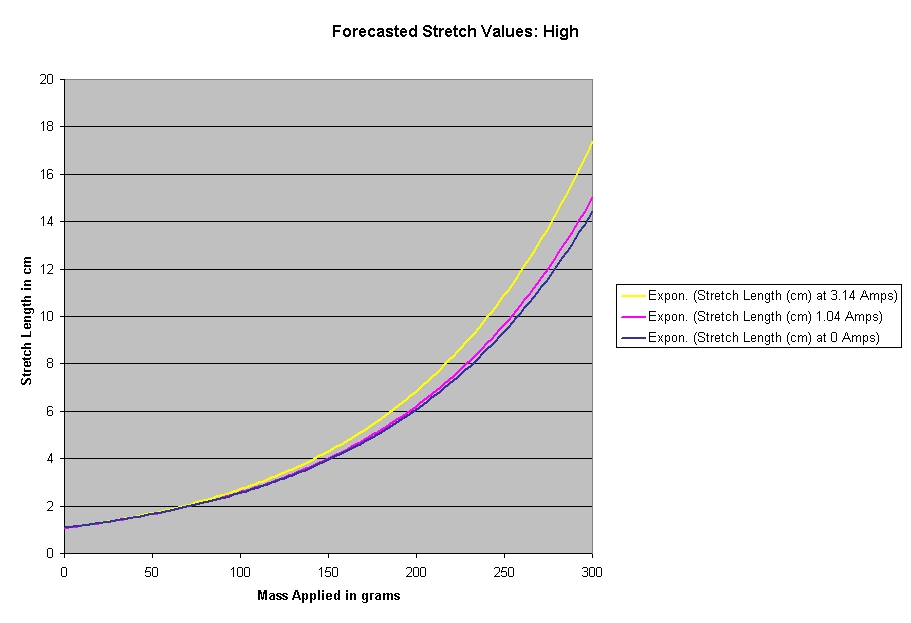

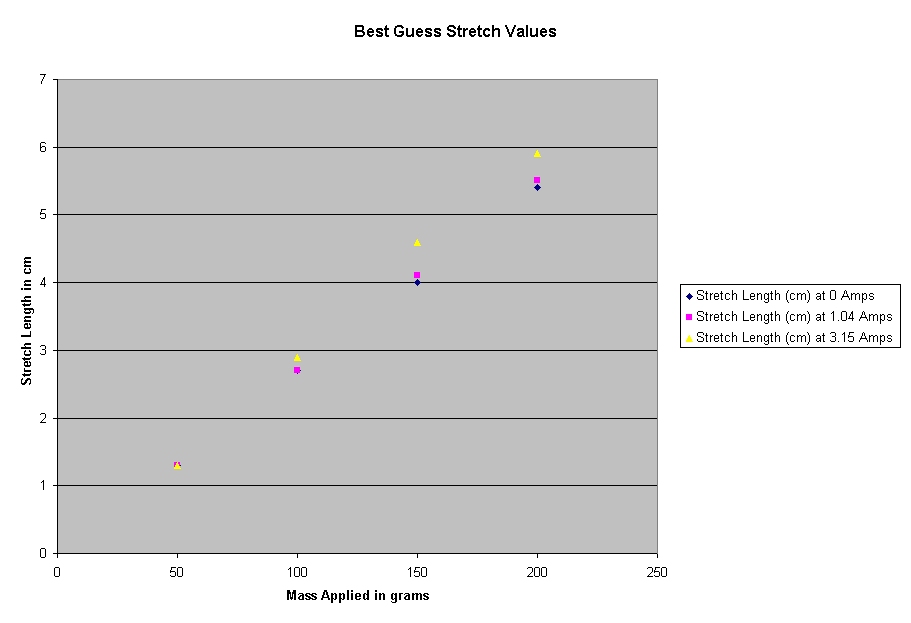

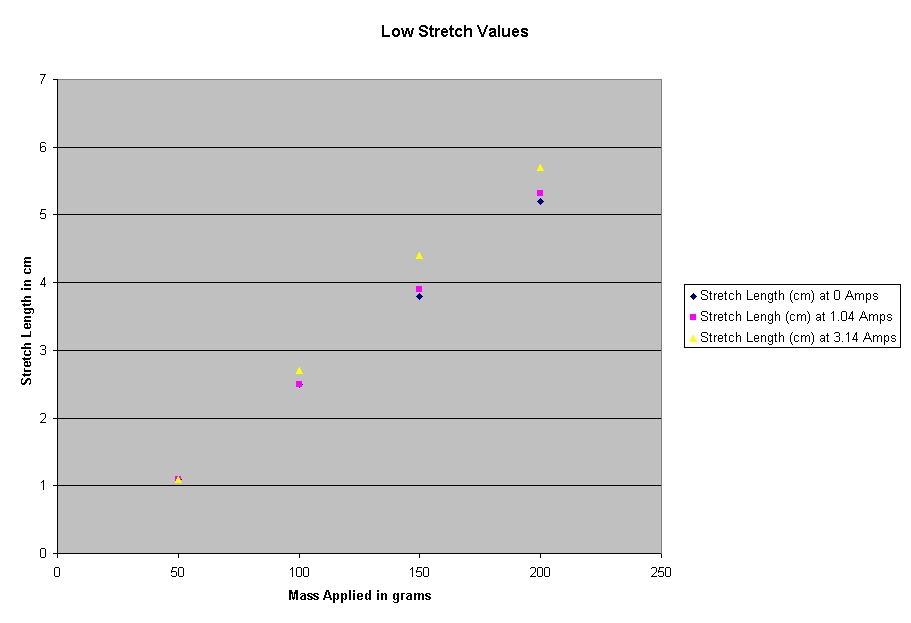

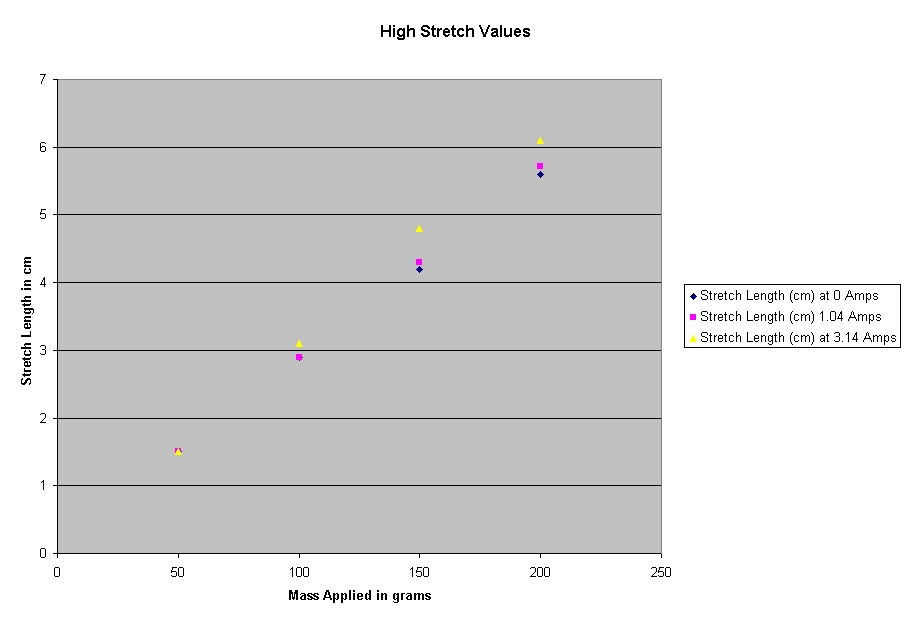

We have calculated an exponential growth for the amount that

each spring stretches with the amount of mass on it for each current. Of

greater significance, however, is that the exponential growth is shown to

increase with the increase of temperature.

Please also note these graphs.

We have concluded

that the spring constant decreases and the exponential growth of the amount of

length stretch increases with the increase in temperature. This is important to

the field of science for multiple reasons. The first of these is that in the

field of mechanical engineering, springs are often used in machines. However,

when work is done by machines, it is usually accompanied by the transformation

of energy into heat energy. This would cause an increase in temperature to the

machine and therefore an effect of the machine’s performance. The decrease in

the spring constant of the machine could lead to dangerous malfunctions and a

decrease of productivity. This information is helpful to mechanical engineers

so they can account for this problem and devise some form of cooling device for

the machines to insure proper functioning.

Furthermore, it could be possible that experiments run in different

environments could lead to a discrepancy in results. For example, an experiment

run outdoors in

Within our data there

are two possible areas where potential error occurred. The first of these is

that during testing, we did not check to see whether the spring, upon removal

of the mass, had reverted back to its previous form. In other words, we did not

check between the masses to make sure the spring had not become plastically

deformed and stretched to a longer length. This could generate room for error

because the amount of length stretched with each mass applied would have been

calculated incorrectly because we subtracted the original length of the spring,

6.5 cm, from the length with mass applied and if the spring did not revert back

to the 6.5 cm then the stretch distance would actually be less than calculated.

To avoid this in the future, it is recommended that the spring length be

measured between each application of mass and then that length be used to

subtract from the corresponding length measurement to calculate the stretch

distance.

The second potential room for error occurred during testing because when

we ran the current of 3.15 Amps through the spring and applied 200 grams mass

to it, upon removal the spring was plastically deformed. For all practical

purposes, the spring remained at the same length it had stretched to while the

mass was applied. Due to this we had to stop testing because our materials

could no longer be used. In retrospect, it would have been better if we had

been able to continue research and get more data to support our hypothesis.

Although we feel we have sufficient data to accept our hypothesis, more would

have been preferred. The lack of data that the deformation resulted in could

lead to room for error because not enough testing was done. Also, the fact that

after the 3.15 Amps the spring was plastically deformed, supports the previous

concern that the spring length should have been measured between each stretch

with mass to ensure we were subtracting the correct length. For the future, we

would recommend that a stronger spring be used and the current be increased in

smaller increments. The stronger spring would allow a higher current to be

reached before becoming plastically deformed and the smaller increments of

increase would allow for the collection of more data.

Although potential room for errors should be taken into consideration when

choosing to either accept or reject our hypothesis, we still feel that we are

able to accept our hypothesis for the following reasons. In reference to the

possibility of the spring becoming plastically deformed during testing and not

reverting back to its original length, we feel that if any permanent stretch

had occurred that was significant enough to really alter our results, it would

have been visibly noticeable and caused us to stop our experiment. Therefore,

if any plastic deformity occurred during testing it was not significant enough

to cause a large miscalculation in data and we feel that because of this our

data is reliable enough to accept our hypothesis. Furthermore, regarding our

having to stop testing prematurely, we still feel that even though only three

current readings were used, because we can notice a marked increase in

exponential growth based upon those three, it is enough to be able to

generalize that had we proceeded to use an increase in current and gain more

data, we would have seen the same marked increase that was visible from the

three exponential equations we were able to originally generate. Therefore,

although we would have preferred more data, it has not handicapped our ability

to accept our hypothesis.

Cook,

J Gordon. Creep of Metals at High

Temperatures.

Isaacs,

Alan. “Elastic Modulus.”

Meiners,

Harry F. Physics Demonstration

Experiments, 1970 ed.

Ridgen,

John S. “Elasticity,” “Elastic Moduli

and Constants.” Macmillan Encyclopedia of Physics, 1996 ed.

Trigg,

George L. “Steel.” Encyclopedia of Applied Physics, 1997

ed.